Wask Equipment

- Pipe Range PE 125-400mm Ø / Steel 80/100-400mm Ø

- Gas free working

- Maximum allowable main pressure 1.5psi

- Metallic and PE pipes

- Interchangeable Noses and Shoes for correct positioning

- 56mm Cut Hole Ø

- Supplied as kit

- Incorporated 1″ vent and purge valve

- Easy replacement of Stopper Bag in case of failure

GET QUOTE

| Pipe Size Range PE | 125-400mm Ø |

| Pipe Size Range Steel | 80/100-400mm Ø |

| Maximum Allowable Main Pressure | 1.5psi |

| Max Bag Inflation Pressure | 3psi |

| Cur Hole Diametre | 56mm Ø |

- PRODUCT DESCRIPTION

- ACCESORIES

- DOCUMENTS DOWNLOADS

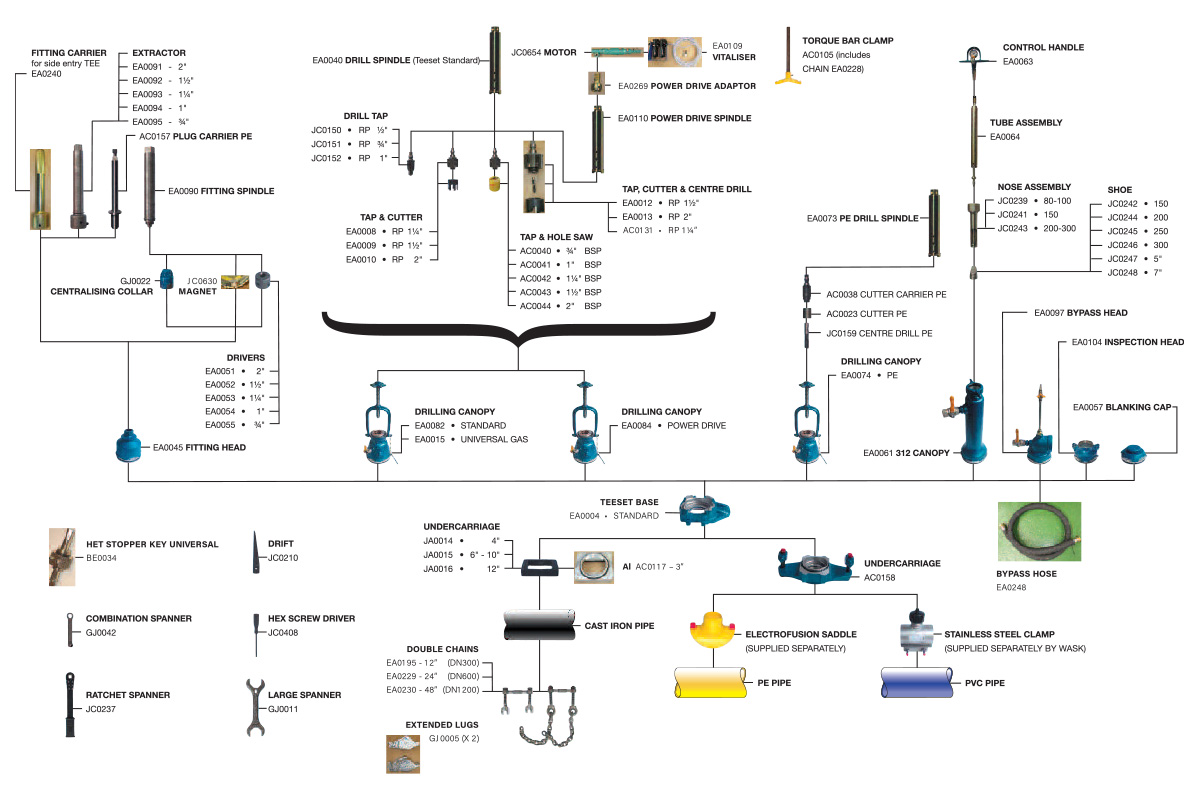

This latest generation equipment enables a temporary flow of gas to be provided around a section of polyethylene or ferrous main which is undergoing maintenance or repair. The WASK Equipment comprises a Canopy enclosing the Bagtube which is mounted on the Teeset base, enabling a Stopper Bag to be inserted through a tapping into the main and inflated to stop the flow of gas.

Sets of interchangeable Noses and Shoes permit the Stopper Bag to be correctly positioned relative to the centre line of the main. Positive support of the inflated Stopper Bag against the gas pressure is provided by the Nose and Shoe assembly. In the event of the Stopper Bag failure, replacement is simple, quick and safe.

Incorporated within the Bypass Head is a 1″ vent and purge valve and a 3/8″ valved pressure test probe which can be inserted through the main tapping into the full gas flow.

Others

PE 125-400mm Ø / Steel 80/100-400mm Ø WASK Gas Equipment

WHATEVER YOUR REQUIREMENTS.

HIRE IT FROM US!

All the poly pipe fusion products and equipment you need to get the job done right, now available at competitive Hire Rates.

Available for daily, weekly or monthly hire, we have a wide range of equipment from Electrofusion Welders and Butt Fusion Machines, to Ancillary Tooling guaranteed to meet your job requirements.

In addition to our well-know support, we also offer Hire Packages and Kits such as Welder, Clamp and Scraper Kits, so you know we are your one stop-shop to get all the equipment you need to get the job done.

Simply fill in the form , detailing your job needs or reference the equipment you are after, and one of our specialists will contact you within 24hrs. You can find all our equipment in our Products Page.

CONNECT WITH US

Caldertech Australia

E: sales@caldertech.com.au | T: +61 (0)8 9209 1132

NSW, QLD and ACT

E: sales@caldertech.com.au | T: +61 (0)7 3185 2175

© Caldertech Australia 2023. ABN 22 164 140 630. All Rights Reserved.